Australia could achieve total COVID-19 vaccine self-reliance within six months and produce enough synthetic vaccine to inoculate the entire nation under a partnership between international biotech giant BioCina and the University of Adelaide.

The venture would give Australia full sovereign capability not only to mass produce mRNA vaccines such as Pfizer and Moderna but also to retool those vaccines in the event of future coronavirus outbreaks and avoid further problems with overseas vaccine supply.

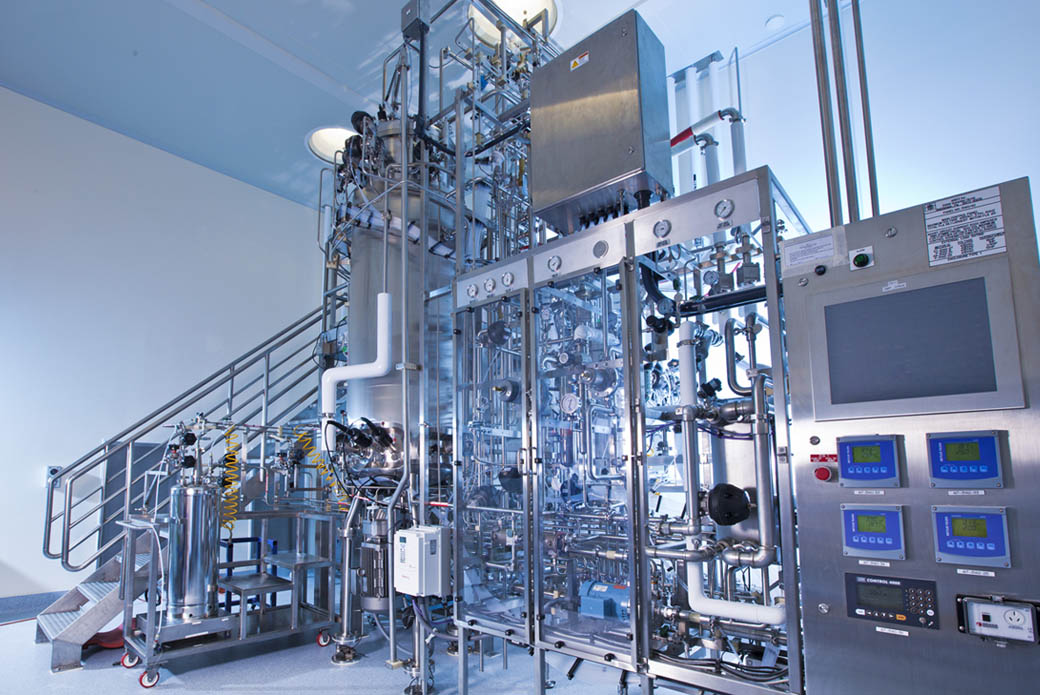

The initiative is a joint venture between BioCina, UA and the South Australian Health and Medical Research Institute that is framed around the purchase of a purpose-built and regulatory-compliant Pfizer biologics manufacturing plant in Adelaide.

Speaking exclusively to The Australian, San Diego-based BioCina chief executive Ian Wisenberg said the fact the plant was ready for use meant Australia could "hit the ground running" with vaccine production

"We are supremely confident that given the green light we could begin manufacture within six months to a year," Mr Wisenberg said.

"In a country like Australia we are talking about 20 million people, or 40 million doses, which is not a lot in terms of production. We see no reason why we could not be producing 100 million doses within that same six to 12-month timeframe, which could also be of benefit to other nations in the Asia-Pacific.

"This is a tremendous opportunity to support the sovereignty of producing vaccines locally and to short-circuit the problems we have encountered with supply chain."

The potential boost emerged as Scott Morrison warned his colleagues in a joint partyroom meeting on Tuesday morning ahead of the budget being unveiled that the pandemic was worse today than a year ago.

This suggests the government will take a cautious approach in reopening the nation’s international borders. Mr Morrison said COVID was "racing" at an unprecedented speed, pointing to countries such as India, Papua New Guinea and Indonesia.

BioCina has spent the past fortnight in talks with UA and SAHMRI finalising its timeline to start production with capital support.

It is hoping to secure just under $100m through private capital or government support as well as securing federal government approval to manufacture the vaccines, which would be made under licence for the relevant pharmaceutical company.

BioCina’s purchase of the Pfizer plant in the Adelaide suburb of Thebarton was finalised last August and since then the company has been working with UA and SAHMRI on plans for production of mRNA vaccines.

Unlike traditional vaccines which contain weakened strains of a virus or purified proteins from a virus, mRNA vaccines use genetic material that encodes the viral protein.

Because mRNA vaccines aren’t created from the virus itself, they can be manufactured more rapidly and on a larger scale, and can be altered more quickly in response to mutant strains of a virus.

The Pfizer plant in Adelaide uses a process called microbial fermentation that produces plasmid DNA, a critical component in a range of modern gene therapies including mRNA vaccines.

"We have a state-of-the-art facility that, with reasonable financial support from government to add key capabilities and expand capacity, can within months be producing key ingredients of mRNA COVID-19 vaccines to address the current global shortage," Mr Wisenberg said.

"Within 12 months we will produce end-to-end mRNA vaccines, like the Pfizer jab, giving Australia sovereignty over its supply."

UA deputy vice-chancellor Anton Middelberg, an international authority on vaccine biomanufacture, told The Australian the project had applications beyond COVID.

"These microbial cells are the workhorses of biotechnology," he said. "Because it is an industrial organism you can very quickly code up a piece of DNA and make a lot of material very quickly. What that means is that if COVID-19 becomes COVID-23 we can be in a position where we can start producing a vaccine pretty much immediately and go from being at the back of the queue to the front of the queue.

"The great thing about this project is that because it uses an existing facility which has regulatory approval, rather than a greenfield site, we can step up right now and start working.

"In terms of advanced manufacturing it has the potential to be a very important part of Australia’s future."

SAHMRI executive director Steve Wesselingh, an infectious diseases specialist, said the technology proposed for use by BioCina was "a game changer for existing diseases, including some which have no current treatment, or new diseases that might arise in the future".

Labor used question time on Tuesday to press Industry, Science and Technology Minister Christian Porter on how many applications the government had received for funding to set up mRNA manufacturing in Australia. Australia does not currently have the technology to manufacture mRNA vaccines at scale.

Mr Porter, who returned for his first question time since he was shifted from the attorney-general portfolio, told parliament there were only a "tiny number of commercial entities" able to produce mRNA vaccines and said the government was already liaising with them.

"There is great confidence for Australia in terms of a capability to manufacture this type of technology, but to ensure that manufacturing is sustainable, that it is commercially viable, and that it is at scale, that will require a breadth of manufacture not just in vaccines but other therapeutic goods, and we’re investigating that at present."

SOURCE: The Australian